Our

Mission

To be the preeminent leader in the manufacturing of dimensionally critical components through unrivaled experiences in tooling design, process monitoring, and statistical quality control, as well as continuous improvement in communication, training, and customer services.

Our Goal

At Xiang Yuan, we are highly driven by the needs of our customers. Being compatible to their needs and excelling their expectations are our utmost goal and propelling force to strive for transcendent performance. Predicated on common goals and interests, we are able to provide unsurpassed services and dedication to enhance our customer's position in their marketplace while promoting our company’s growth; maintaining a mutually beneficial partnership with our customers. To accomplish our goals and sustain our visions, the followings are warranted:

Globalized customer Services

- San Francisco international sales office

- 24-hour operating factory

“Just-In-Time” Delivery

- Work closely with our customers

- Adapting our schedules to ensure delivery on time

- Available to stock the ongoing products at San Francisco warehouse

Fixed Material Price

- We offer a fixed pricing for a set period of time

- During the predetermined timeframe, we do not implement a price increase to our customers to compensate the higher cost accrued from inflation

Reduced Tooling Lead Time

- For smaller Zinc tooling

Reduce the lead time from the typical 30 working days of our competitors to 20 days or less - For larger Aluminum tooling

We could have our first article ready by the 30th day starting from the day we receive the final design drawing, in comparison to the standard 45 days that is commonly set within the industry

Reliable Automation

- We acknowledge the importance of quality. We strongly believe world-class quality is attained from high degree of automation, not from random human defects. Reducing hand manipulation and its subsequent inaccuracies, automation systems are capable of productivity gain, higher yields, enhanced precision, and zero-defect quality.

Industry Served

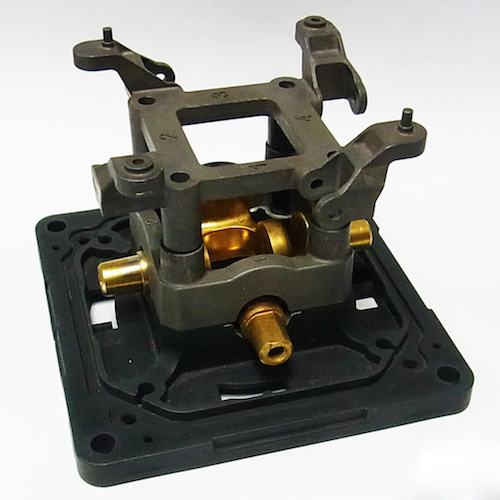

- Connectors

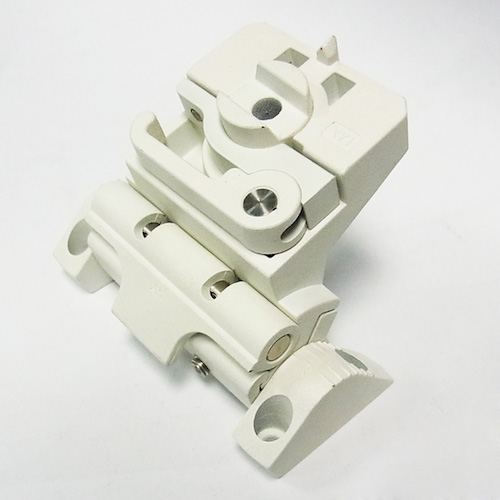

- Hinges

- Computer standard parts

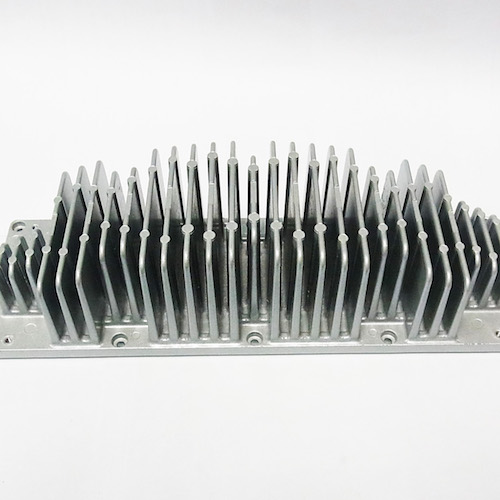

- Automotive Heat Sink

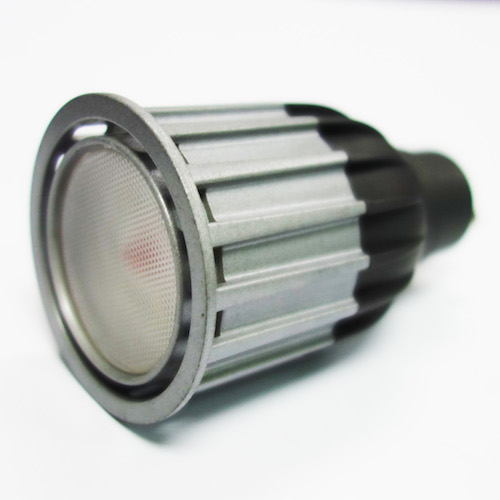

- Lighting Housing

- Pneumatic Valves

- Recreation

- Fax Machine

- Scanner

- Telecommunication

- Medical equipment

- Lighting Housing

- Kitchenware

- Sunglasses parts

Head Office:

Xiang Yuan Precision Die Casting Co. LtdRoom 1207, 22/F, Tuen Mun Central Square, 22 Hoi Wing Road, Tuen Mun, N.T.

Tel: (852) 24630268

Fax: (852) 24639163

Email: sales@xypdc.com

China Factory:

Xiang Yuan Precision Die Casting(Dongguan) Co. Ltd.

Shichong Industrial Park, Shipai Town, Dongguan City, PRC

Tel: (769) 88652666

Fax: (769) 86651549

USA Office:

Mytrucknation Inc.240 Dollar Ave, South San Francisco, CA 94080

Tel: 1 877 618 8860